- Joined

- Aug 7, 2025

- Threads

- 4

- Messages

- 31

- Reaction score

- 86

- Location

- United States

- Vehicle(s)

- 2024 Tundra TRD Off Road, 2024 Tacoma TRD Off Road

- Thread starter

- #1

Hey everyone! We're excited to give you an early look at what we've been working on behind the scenes here at SXTH.

As we continue developing our comprehensive upgrade system for the 4Runner, Tacoma, and Land Cruiser, we're focused on optimizing every component in the boost path. While our intake and intercooler are the headline items, we know that the connecting pieces are just as critical to overall system performance.

That's why we're giving the same engineering attention to the turbo inlet, throttle inlet, and charge pipes; components that are often overlooked but can have a massive impact on spool response, efficiency, and peak power delivery.

Turbo Inlet: The Journey to CFD 3

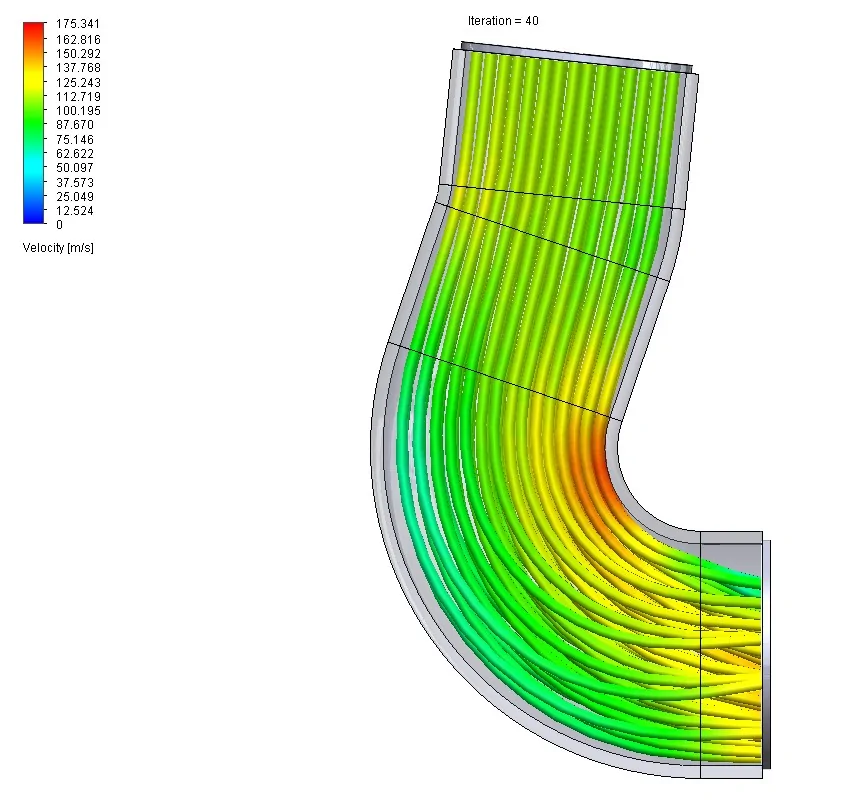

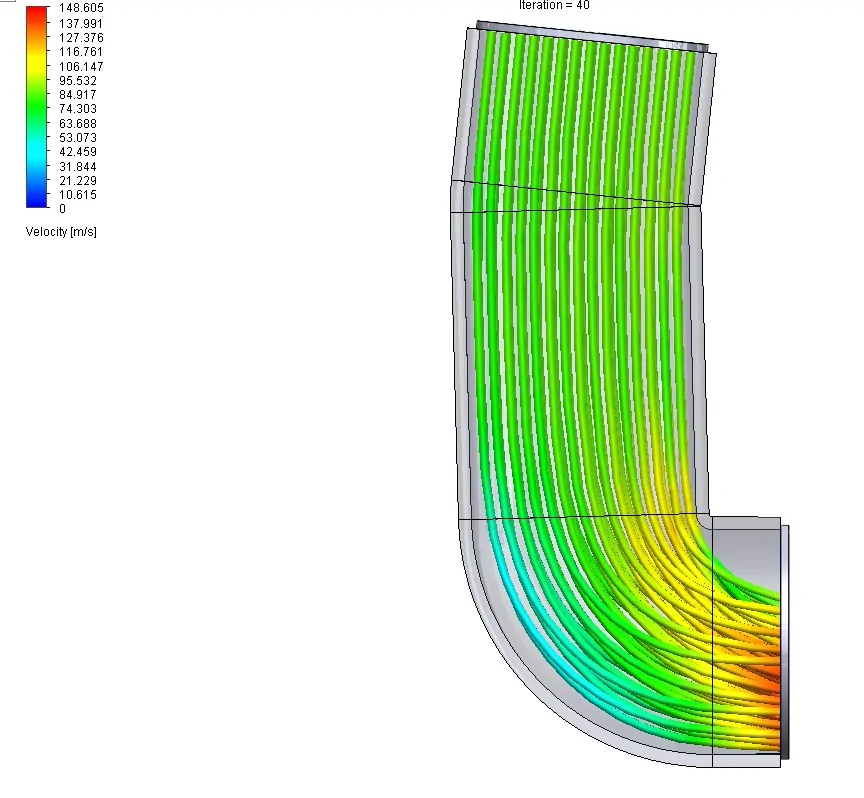

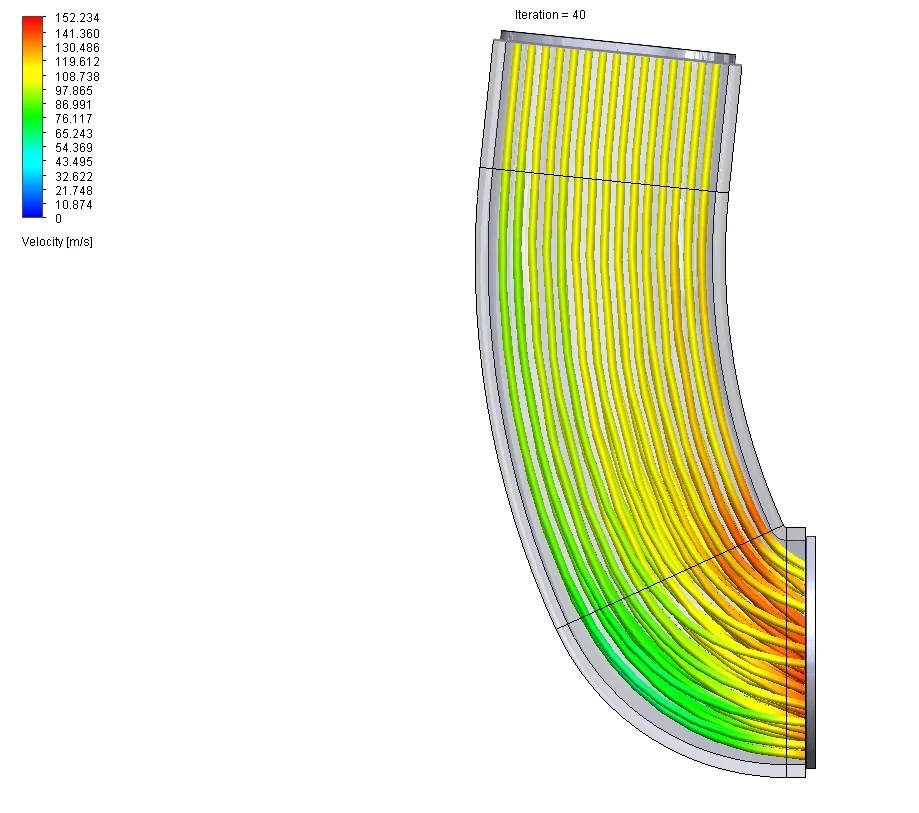

Today we're sharing an early peek at our replacement turbo inlet, and the progress speaks for itself. Our engineering team has been iterating aggressively using computational fluid dynamics (CFD) analysis to eliminate flow restrictions and turbulence that you find in OEM designs.

The Challenge: Stock turbo inlets are designed as compromises, they balance manufacturing simplicity with decent performance. This typically means suboptimal flow paths, rough internal transitions, and velocity losses right at the turbo's inlet where every bit of efficiency matters.

Our Solution: Through multiple CFD iterations, we've developed a replacement inlet with dramatically smoother flow characteristics. Compare the progression you see here:

.

.

.

.

The results are clear in the CFD analysis: higher, more uniform velocities across the entire flow path and significantly smoother air delivery to the turbocharger.

What This Means for You

A better turbo inlet translates to:

Faster Spool: Smoother flow path = less pressure drop = turbo spools quicker and builds boost faster

Better Response: Eliminate the dead zones and you eliminate the hesitation. You get more responsive throttle input and better transient response

Improved Efficiency: Higher velocity with less turbulence means the turbo works smarter, not harder. Better efficiency = more power at lower turbo speeds

Cooler Charge: Reduced friction losses mean less heat generation before the intercooler. Denser, cooler air = more power

This is just the beginning. We're applying this same CFD-driven iterative approach to the throttle inlet and charge pipes. Every component in the boost path matters, and we're treating it that way.

More updates coming soon. Stay tuned!

As we continue developing our comprehensive upgrade system for the 4Runner, Tacoma, and Land Cruiser, we're focused on optimizing every component in the boost path. While our intake and intercooler are the headline items, we know that the connecting pieces are just as critical to overall system performance.

That's why we're giving the same engineering attention to the turbo inlet, throttle inlet, and charge pipes; components that are often overlooked but can have a massive impact on spool response, efficiency, and peak power delivery.

Turbo Inlet: The Journey to CFD 3

Today we're sharing an early peek at our replacement turbo inlet, and the progress speaks for itself. Our engineering team has been iterating aggressively using computational fluid dynamics (CFD) analysis to eliminate flow restrictions and turbulence that you find in OEM designs.

The Challenge: Stock turbo inlets are designed as compromises, they balance manufacturing simplicity with decent performance. This typically means suboptimal flow paths, rough internal transitions, and velocity losses right at the turbo's inlet where every bit of efficiency matters.

Our Solution: Through multiple CFD iterations, we've developed a replacement inlet with dramatically smoother flow characteristics. Compare the progression you see here:

- CFD 1: Our first iteration showed improvement, but we identified areas where the flow was still separating and losing energy

- CFD 2: Refined geometry with better transitions, moving closer to the ideal

- CFD 3: Our final design—the winner. This version features optimized internals that maintain consistently high velocity throughout the inlet tract while eliminating dead zones and turbulence

The results are clear in the CFD analysis: higher, more uniform velocities across the entire flow path and significantly smoother air delivery to the turbocharger.

What This Means for You

A better turbo inlet translates to:

Faster Spool: Smoother flow path = less pressure drop = turbo spools quicker and builds boost faster

Better Response: Eliminate the dead zones and you eliminate the hesitation. You get more responsive throttle input and better transient response

Improved Efficiency: Higher velocity with less turbulence means the turbo works smarter, not harder. Better efficiency = more power at lower turbo speeds

Cooler Charge: Reduced friction losses mean less heat generation before the intercooler. Denser, cooler air = more power

This is just the beginning. We're applying this same CFD-driven iterative approach to the throttle inlet and charge pipes. Every component in the boost path matters, and we're treating it that way.

More updates coming soon. Stay tuned!

Sponsored